EXAMPLE Real-Time Monitoring of Micro-3D-Inkjet-Printing

This is an example on how a challenge could look like:

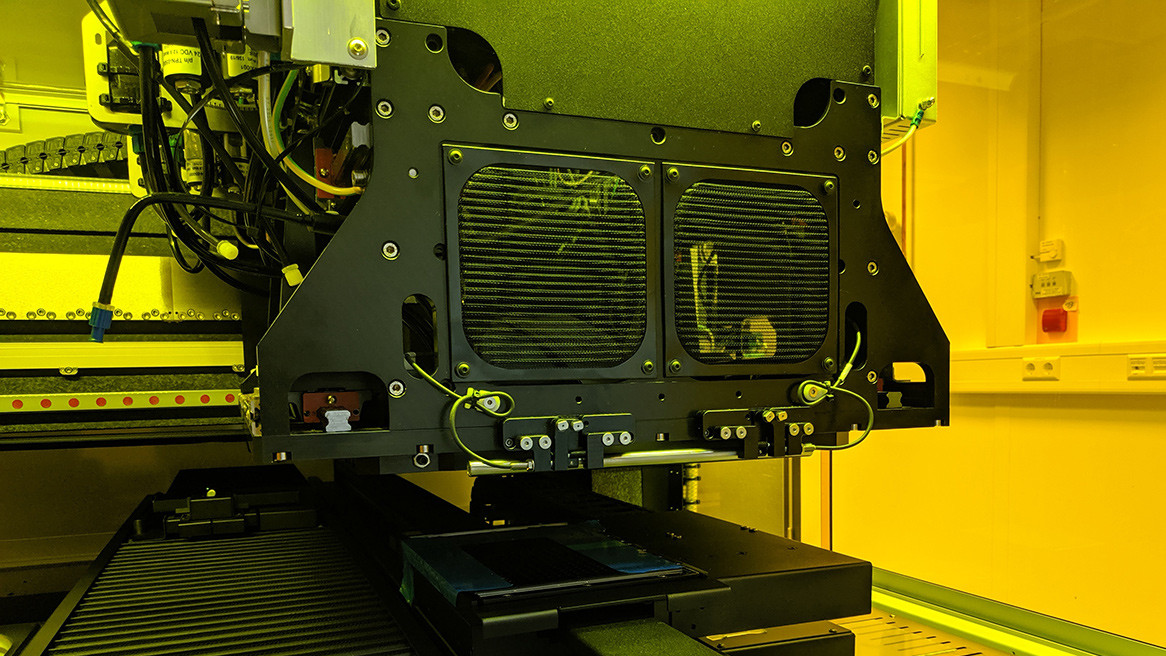

The aim of this project is to develop a in-line inspection system at TRL 3-4 for real-time monitoring a additive manufacturing process done by 3D inkjet printing.

3D inkjet Printing is capable of producing small-scale complex objects with high precision. However, due to its high resolution in z-axis and precision the printing process is slow compared to other techniques and can take hours or even days to complete. Therefore, a constant inspection and identification of errors is necessary to avoid prints that fail at an early stage and are carried out for a long time, thereby wasting precious time, energy and materials.

The challenge in developing a 3D inspection system for this process is twofold. First, the camera(s) have to have resolution that is high enough to detect faults in the print with single lines being in the range of tens of microns. Secondly, the geometry and layout of the machine prevents the system of being close to the print itself since the printhead moves only 1 mm above the printed surface.

We are experienced in 3D inkjet printing with state-of-the-art inkjet printers.

We are looking for research partners with expertise in the development of in-line inspection systems, optical sensors as well as system integrators capable of developing such a system.

Author

No files

- Quality of the researcher

- TRL of provided research

- Fit to the topic (experience)

- Location of researcher

- References

0