Performance Monitoring and Safety Systems for Mobile Industrial Welding Cell

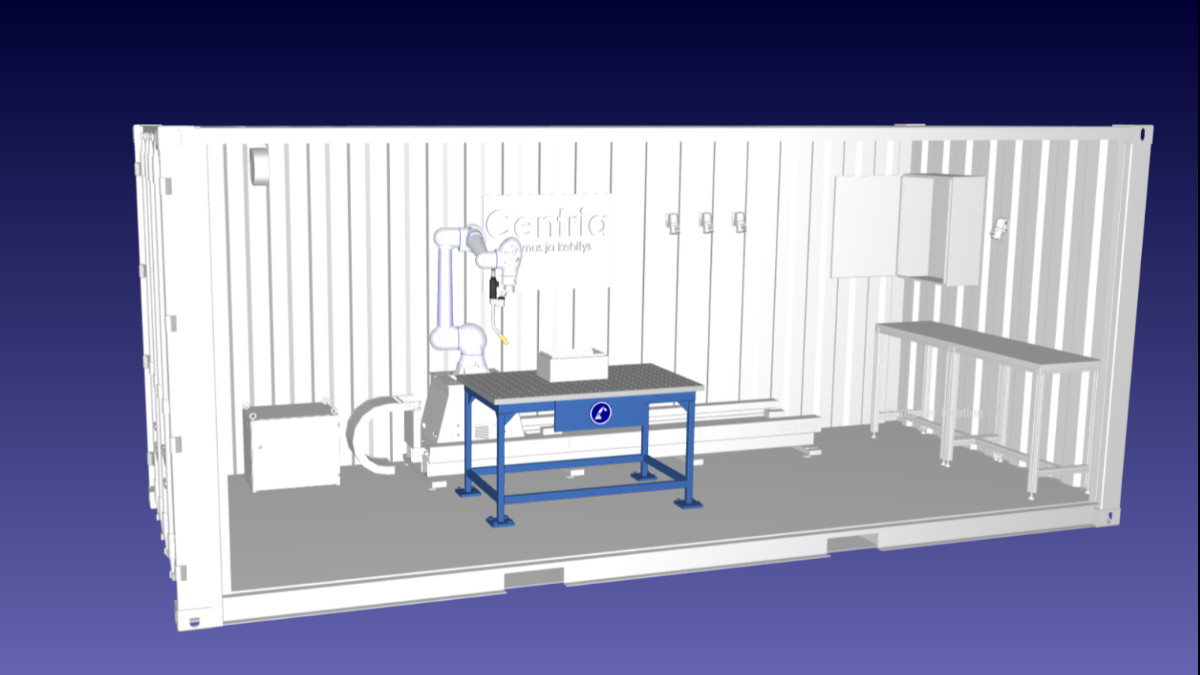

A robotics lab has developed a mobile industrial welding cell for research and rapid demonstrations of robotized MIG/MAG welding. The system consists of a collaborative robot, linear track and a MIG/MAG -welding system, integrated into a standard 20-foot shipping container. Collaborative robots are inherently designed with heightened safety features and usability for non-experienced operators. However, the linear track is not designed to be collaborative, which presents safety hazards. Figure 1. presents the mobile industrial welding cell.

We invite innovative minds to participate in improving the Performance Monitoring and Safety Systems for Mobile Industrial Welding Cell. Your task is to perform a premeditative risk assessment and design an effective safety system that can reliably monitor, detect and mitigate risks presented to a non-experienced operator. Your design should prioritize the safety of operating personnel.

Additional task is to design a system that can monitor the welding process in real time and provide data to operators and end-users about the process. This data helps operators in deciding what parameters to adjust to improve quality of the process. The system should be scalable in order to implement automatic adjustments in the future.

Note:

- The safety system should be cost-effective, reliable, and capable of operating in a high-precision, fast-paced automation environment to prevent hazardous situations. The system should be designed in compliance with effective safety standards.

- The performance monitoring system data may include anything process-related that may be used in process adjustment. ie. welding current, camera image, etc.

- Regarding both systems, a clear presentation of system infrastructure should be included.

Author

No files

Solutions will be evaluated by Sami Sarlin and Jukka Saarela. Evaluation will be carried out based on the following criteria:

- Safety and security

- Novelty

- Suitability

- Cost-effectiveness

Credits for Centria students